Professional 3D Printing

Ultem

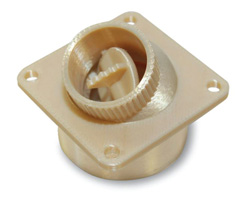

ULTEM is known for its high thermal performance and strength-to-weight ratio. Used by many in the transportation industry, ULTEM prototypes can be made for fully functional parts or as functional prototypes in heat sensitive applications. This flame retardant, high performance thermoplastic can meet the demands of your heat resistant application and perform well as a functional prototype or final part saving you thousands of dollars when compared to the costs of traditional tooling.

| MECHANICAL PROPERTIES | TEST METHOD | ENGLISH | METRIC |

|---|---|---|---|

| Tensile Strength (Type 1, 0.125", 0.2"/min) | ASTM D638 | 10,400 psi | 71.6 MPa |

| Tensile Modulus (Type 1, 0.125", 0.2"/min) | ASTM D638 | 322 kpsi | 2,200 MPa |

| Tensile Elongation (Type 1, 0.125", 0.2"/min) | ASTM D638 | 6% | 6% |

| Flexural Strength (Method 1, 0.05"/min) | ASTM D790 | 16,700 psi | 115.1 MPa |

| IZOD Impact, notched (Method A, 23°C) | ASTM D256 | 2.0 ft-lb f/in | 106 J/m |

| IZOD Impact, un-notched (Method A, 23°C) | ASTM D256 | 11.5 ft-lb f/in | 613.8 J/m |

| Compression Strength | ASTM D695 | 15.2 ksi | 104 MPa |

| Compression Modulus | ASTM D732 | 280 ksi | 1930 MPa |

| Shear Strength (0.25" thick coupon) | ASTM D732 | 8.3 ksi | 57 MPa |

| THERMAL PROPERTIES | TEST METHOD | ENGLISH | METRIC |

|---|---|---|---|

| Heat Deflection(HDT)@ 66 psi, 0.125" unannealed | --------------- | --------------- | --------------- |

| Heat Deflection(HDT)@ 264 psi, 0.125" unannealed | ASTM D648 | 307°F | 153°C |

| Glass Transition Temperature (Tg) | DMA (SSYS) | 367°F | 186°C |

| Coefficient of Thermal Expansion | ASTM E228 | 3.67e-05 in/(in·F°) | 65.27 μm/(m·C°) |

| Melt Point | --------------- | Not Applicable | Not Applicable |

| ELECTRICAL PROPERTIES | TEST METHOD | VALUE RANGE |

|---|---|---|

| Volume Resistivity | ASTM D257 | 1.0 x 10e14 - 6.0 x 10e13 ohms |

| Dielectric Constant | ASTM D150-98 | 3.2 - 3.0 |

| Dissipation Factor | ASTM D150-98 | .0027 - .0026 |

| Dielectric Strength | ASTM D149-09, Method A | 290 - 110 V/mm |

| OTHER | TEST METHOD | VALUE RANGE |

|---|---|---|

| Specific Gravity | ASTM D792 | 1.08 |

| Rockwell Hardness | ASTM D785 | R108 |

| Flame Classification | UL 94 | HB (0.059", 1.5 mm) |